Laciny Bros. Continues to Craft Growth

When someone asks Tim Laciny what he does for a living, he usually responds with question of his own. He asks how much time they have to chat.

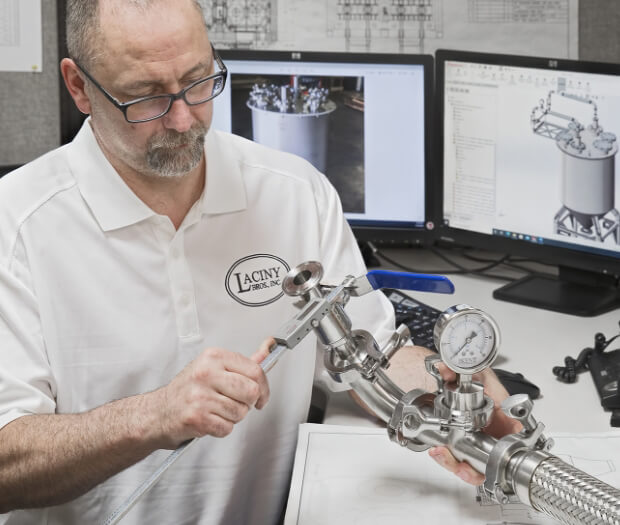

“That’s because custom metal fabricating is such a broad thing,” said Laciny, president and owner of University City-based Laciny Bros.

Laciny Bros., founded in 1916, provides customized metal fabrication of manufacturing equipment for several industries, including pharmaceutical and food processing companies. Clients have included Anheuser-Busch InBev, ConAgra Foods, Nestlé Purina PetCare and Mallinckrodt Pharmaceuticals.

“We make products that make the products that people use everyday. We have done things in this town you would never know we did, but our fingerprints are all over it,” said Laciny. “We’ve been around such a long time that people have come across our work, they just don’t know it.”

Brothers Victor, Leopold and Carl Laciny established Laciny Bros. in 1916. The brothers immigrated to the U.S. from Eastern Europe and Russia and put up $23 each to begin their company. Today, Tim Laciny represents the fourth generation to lead the company. He took over as sole owner in 2013. His father, Bob, assumed ownership of Laciny Bros. in 1998. Don O. Laciny, the great uncle of Tim Laciny, became president of the company in 1965. His great aunt Arleen Laciny Ulz, who passed away in October, became president of the company in 1991.

For Tim Laciny, working at he company after his graduation from the University of Missouri-Columbia was a no-brainer. He and his brother, Rob, joined the company in 2001. Rob no longer works with the company.

“For me personally, I came to work here when I was 14 and I had always spent my summers here. I didn’t picture working anywhere but here,” Tim said.

Throughout its 100-plus year history, Laciny Bros. has charted growth both in size and through innovation. The company has operated at four different locations and moved into its current location — its largest yet — at 6622 Vernon Ave. in University City in 1990. It also invested in engineering to expand its customization efforts and to serve a wider array of industries. Laciny said the company’s equipment and methods are a “proper blend of old school and new school.”

One of biggest challenges for Laciny Bros. in recent years has been staffing, with the company saying that the physical demands of being a metal craftsman and the training it requires can make finding employees difficult. The company has relied on longtime employees who have trained younger staff and served as mentors, Laciny said.

“As long as there’s people out there who want to work hard and they want to learn a skilled trade and be the best that they can be, that’ll keep us in business,” he said.

As for the Covid-19 pandemic, Tim Laciny said it's had a minimal impact on the business because of its focus on serving clients in essential industries such as pharmaceuticals and food processing.

Laciny Bros has 33 employees and $6.5 million in annual revenue. Whether a fifth generation eventually runs the company remains to be seen. Tim Laciny has three children and said he hopes another generation can advance the company's legacy of supporting the employees that have kept the company going for more than a century.

“When my dad passed away, one of the things that motivated my brother and I to keep it going was to take care of the guys who take care of our family. I’d like to do that for another generation and I hope my kids get to do it,” he said.

— Content and Images courtesy of St. Louis Business Journal